| « La Lune s'éclipse le 28 septembre 2015 | NON au cinéma 3D avec lunettes ! » |

16/04/2015

Ion sensitive electrodes preparation

3. Pulling.

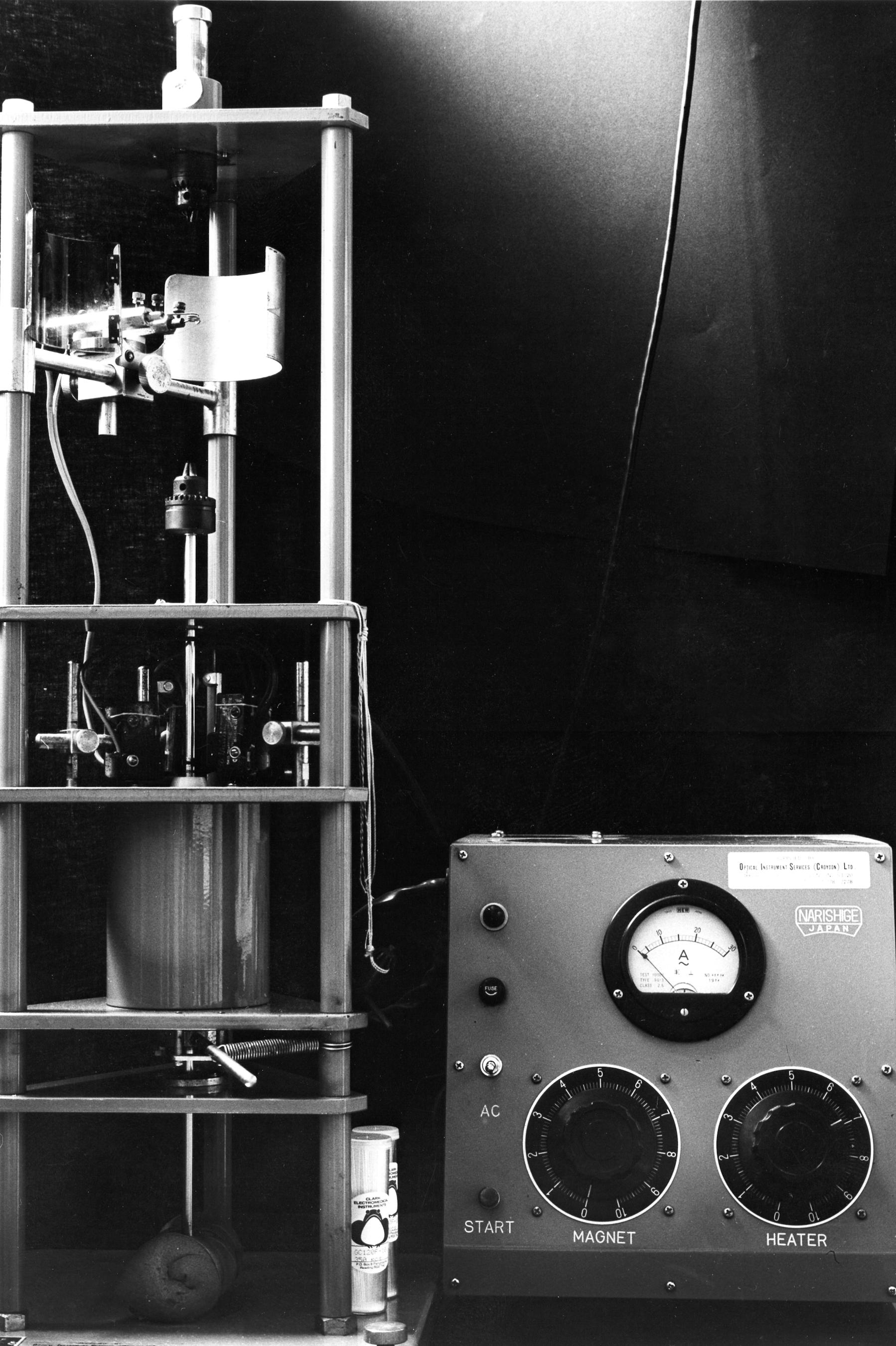

In order to make a micropipette out of our double barrel assembly, we choosed to use a vertical micropipette puller. The model we used is an old Narishige (TM) one (see picture 1 below), but different new model are available from Narishige and others (i.e. Sutter). The important point, as will be seen in the procedure description, is the fact that the automatic magnetic pulling can be deactivated. Another point is the size of the oven (heating filament) which should be large enough to allow the tubings assembly to get through. Using an horizontal puller is probably not possible, but we never tried.

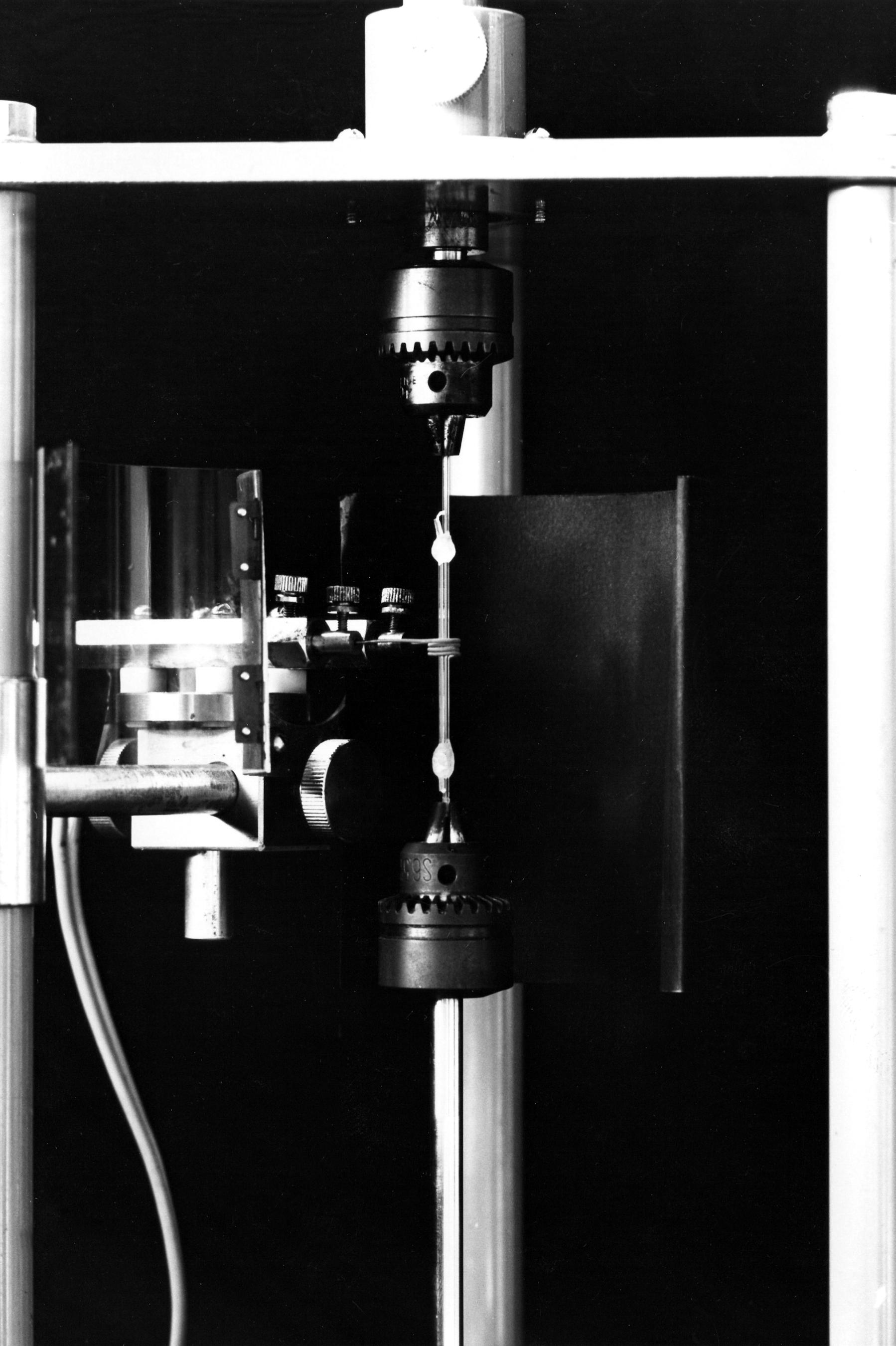

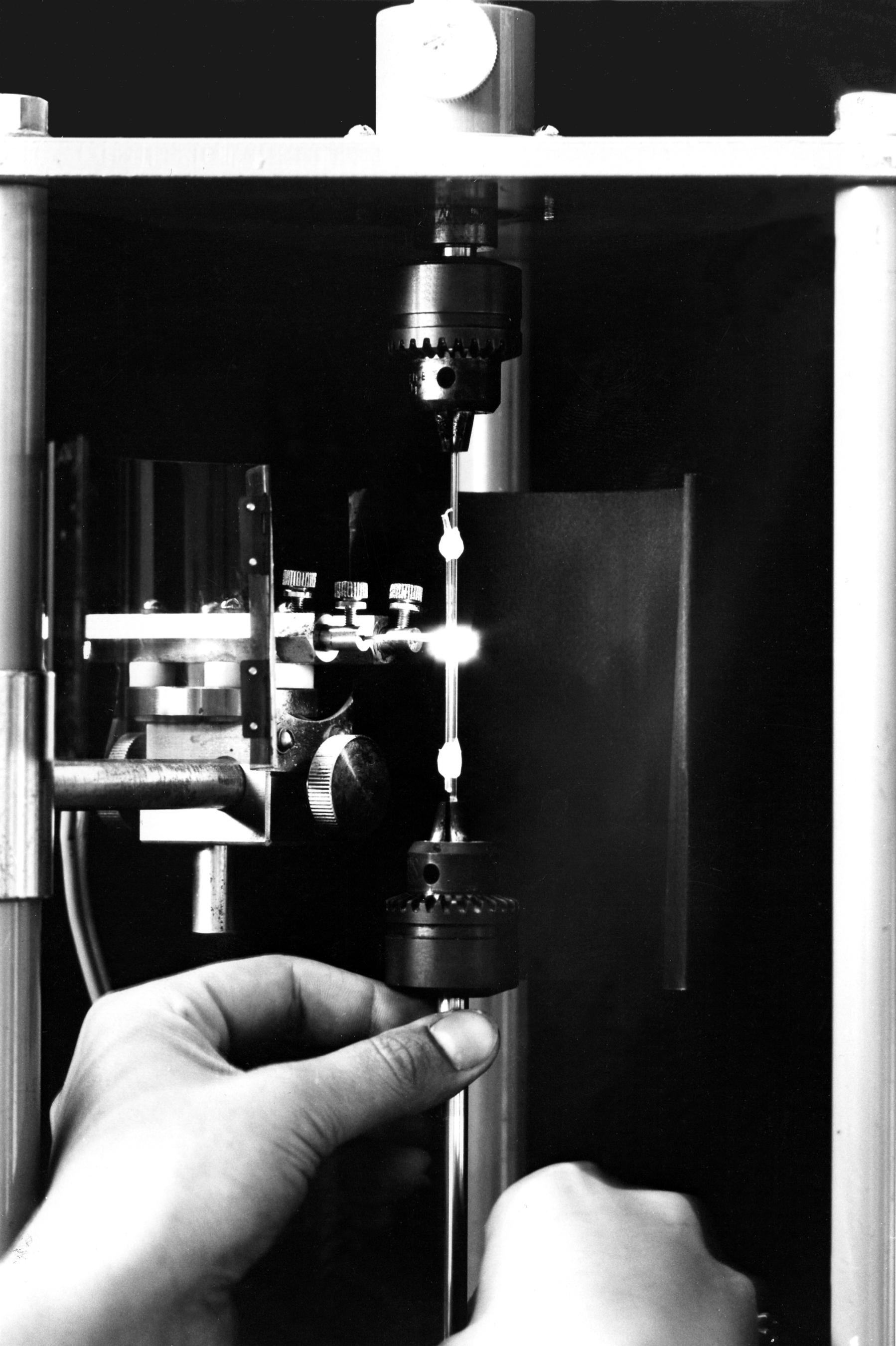

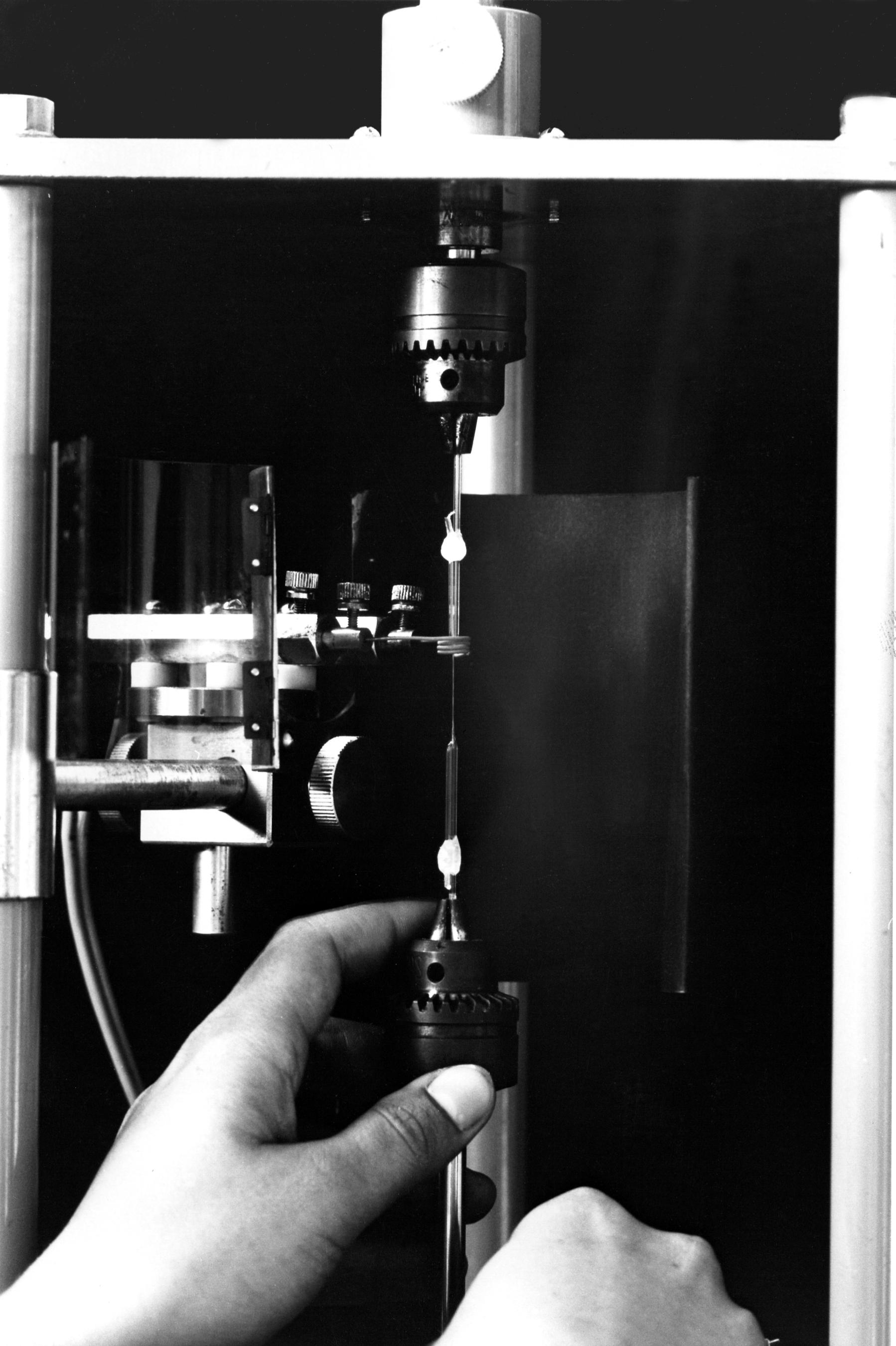

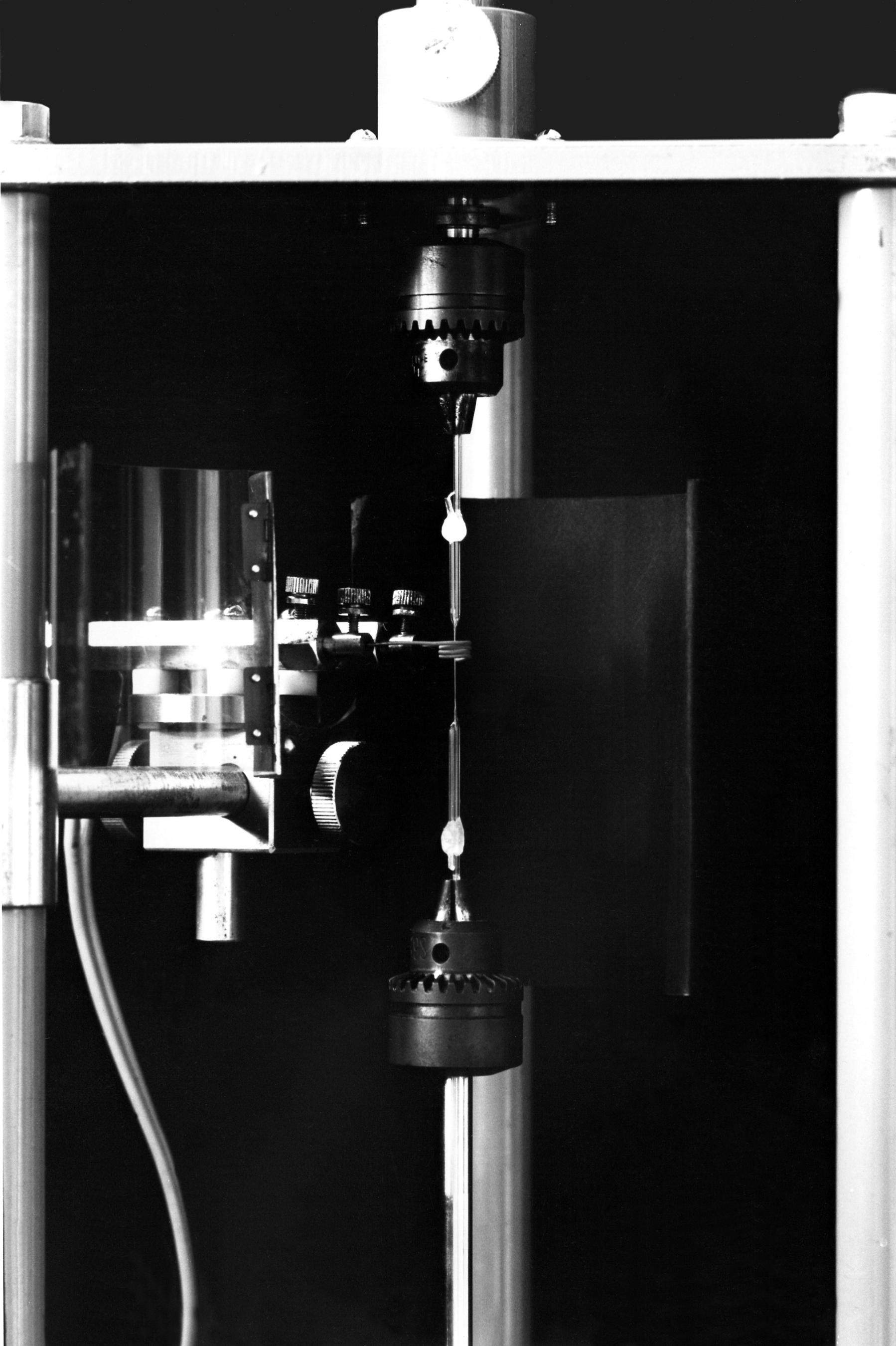

Pulling procedure. Of course, the heating has been beforehand calibrated for the different steps of the procedure. The tubings assembly is inserted through the heating filament and fixed on both ends with the drill chucks systems (pict. 2). The magnetic puller is deactivated. The lower part of the system is held firmly by hand and the heating is started. When the glass melts, the lower system is slowly turned (about one turn) without moving vertically (pict. 3). Without this step, one would get two separate tips instead of a single one. Then the lower system is allowed to fall by gravity under hand control to form a reduced diameter capillary of about 2-3 cm long and the heater is stopped (pict. 4). Click on the small pictures to enlarge.

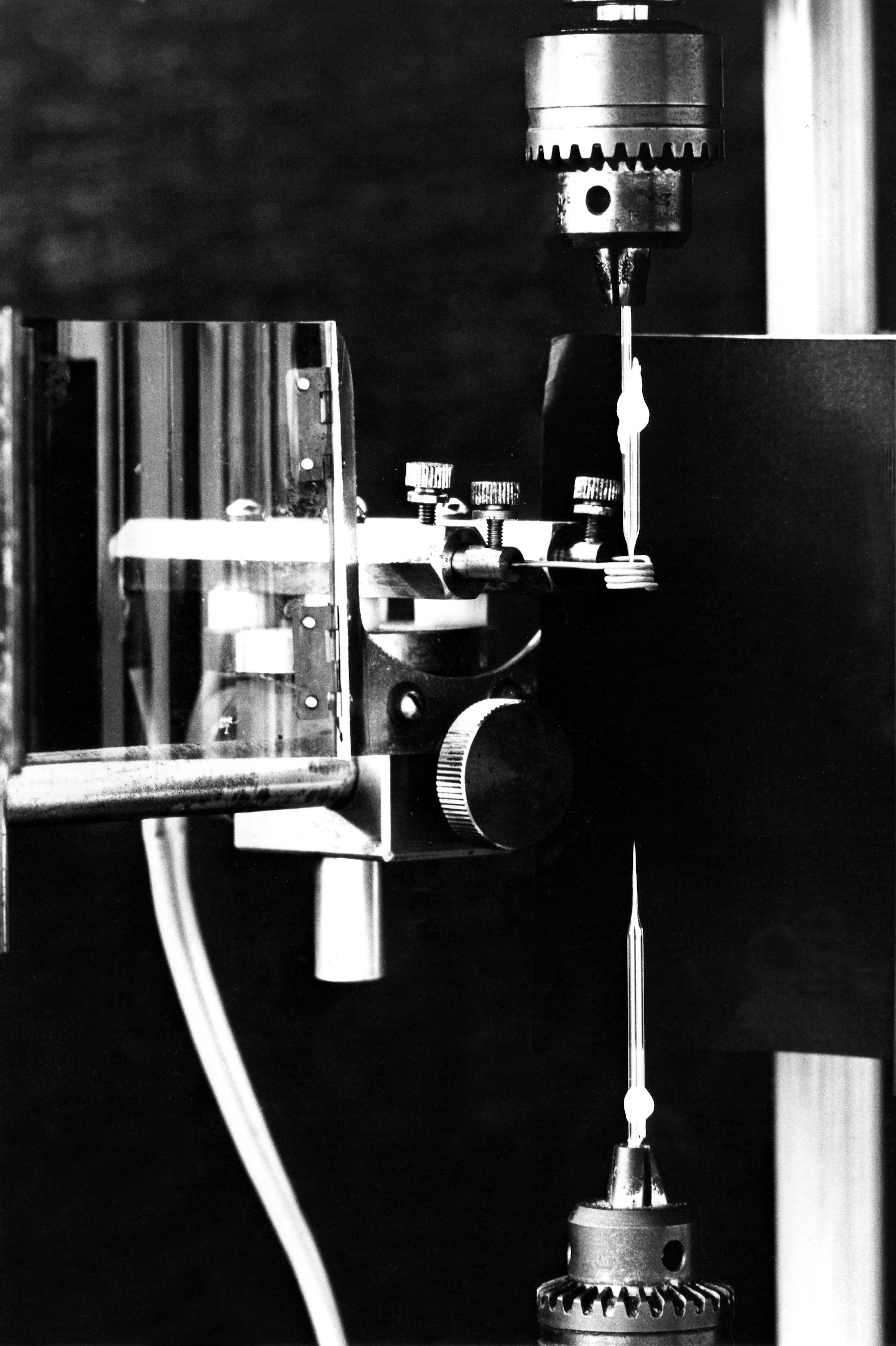

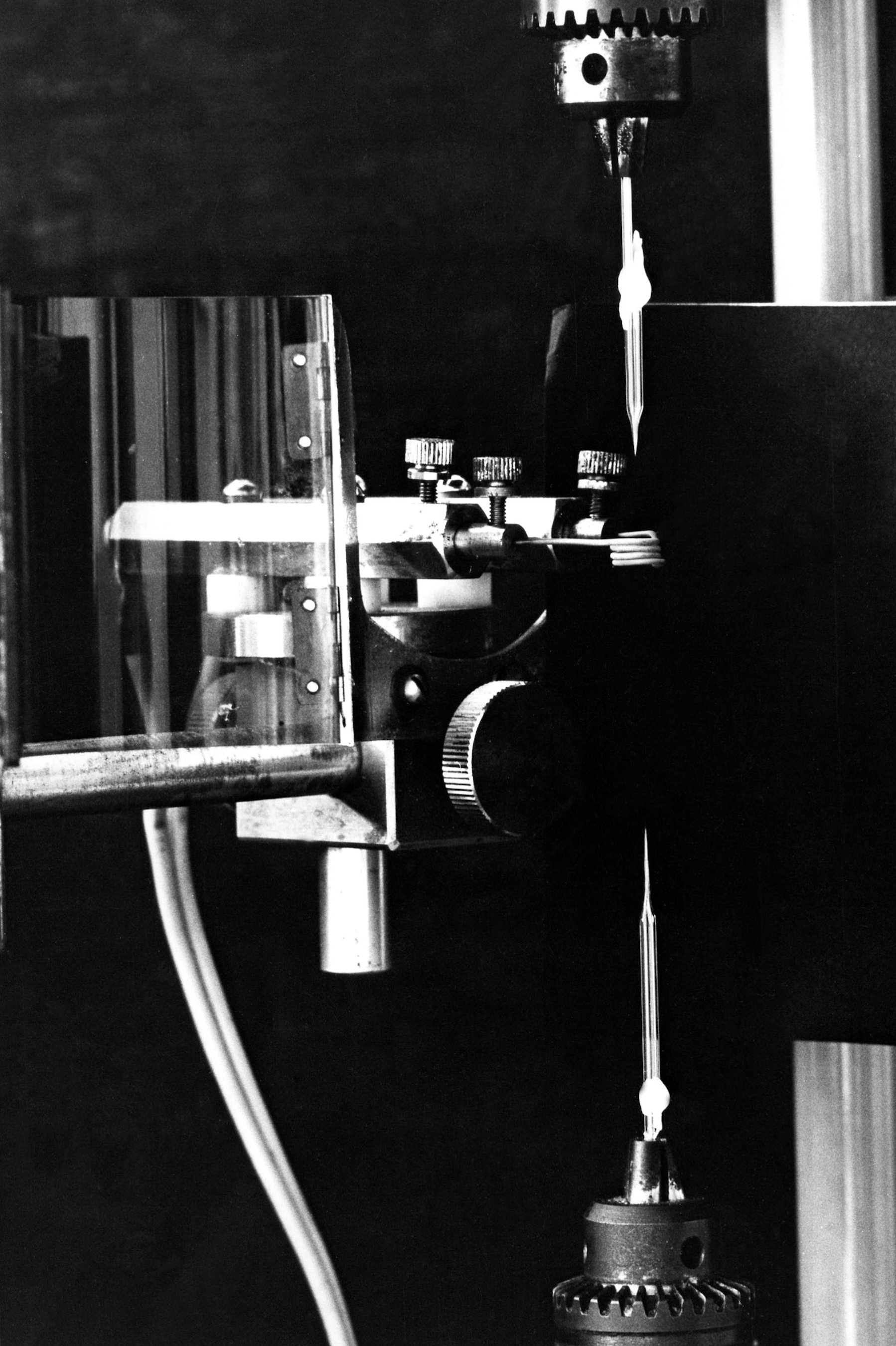

In a second sequence, the magnetic pulling is allowed and the heating is set to the parameters for a final pull. The upper system is moved slightly up so that the shoulder that has been formed on the glass capillaries during the previous sequence is now higher than the heating element (pict. 5). The heating and pulling are activated to form the tapered tip (pict. 6 and 7). The parameters are adjusted so that the tip diameter is in the range 1-3 µm. The filling of the "ionic side" will be more difficult as the tip size decrease.

Now that we have made our double barrel micropipette, we shall have to fill it. Please see next page (click here or select page 3)

No feedback yet

Form is loading...